Electric – Nissan Figaro Electric Conversions

Today, everyone seems to be talking about electric vehicles, and many Figaro owners are obviously wondering if it’s possible to convert the car to electric. The desire to travel in silence, produce zero emissions, and save money on fuel is becoming increasingly viable as battery technology continues to improve.

Below, we have featured three conversions and provided links so you can learn more about the complexities of the conversion.

BUILDER: PAUL JONES

Builder: Paul Jones

Country: Wales

Email: rhydavonpaul@outlook.com

Date: 15/10/2025

Name: Frankie

Range: 120 Miles

Charge Time: 4 hours

Battery Type: Lithium from VW ID Buzz

Mission: To create a usable and repeatable electric Figaro conversion

Backstory. My wife has always been a Figaro fan and has had two in the past, a Topaz Mist and a Grey (which was sadly written off!) After a brief spell using my new electric BMW i3 in 2014, she decided that it should now be hers and commandeered it, which led to a succession of new electric cars, including another BMW i3 and a Honda E. With her retirement looming, we came up with a plan. Why not get another of your favourite cars, a Figaro, and bring it up to date by electric-converting it? A quote of £50,000 from a reputable conversion company sent me down the route of doing it myself. How hard could it be? Very hard, as it turned out!

The first challenge was finding a cheap, rust-free Figaro, not exactly an easy task, as the thought of doing a body restoration and an electric conversion seemed like a task that would take the rest of my life! After about two years of searching, a candidate was found in a shipping container with a blown engine, exactly what I was looking for!

SEE PICTURE 1 BELOW.

The obvious place to start would be to transplant the whole package out of a Nissan Leaf, motor stack, batteries, etc. I realised very quickly, helped by James Brown, that this was impossible: the motor stack would be sticking out the top of the bonnet by about a foot, and the battery pack would have taken up both boots and necessitated the removal of all four seats, hardly a practical proposition.

I decided to find the most compact motor/gearbox combination with the most modern, energy-dense batteries available.

Initial attempts using CAD and WAD (Cardboard and Wood Aided Design) SEE PICTURE 2 BELOW.

Various pieces of Mitsubishi and Toyota components were test-fitted to no avail. Nothing really fitted well enough to be viable. I had, however, decided to bite the bullet and source a motor (Hyper9) and some batteries (4x VW ID Buzz modules.) By now, I had invested enough money that I had to find a way to do it! The breakthrough came when the batteries were shipped from Northern Ireland, and I asked the company to send a subframe from the smallest electric car I could find. I only did this to give me ideas of how to mount the motor into the car, but to my surprise, this subframe fitted inside the Figaro engine bay! With the addition of the original Figaro engine mount,s this could be a good starting point, using the original gearbox (reduction unit) that matched the subframe and adapting the motor to fit the subframe /gearbox.

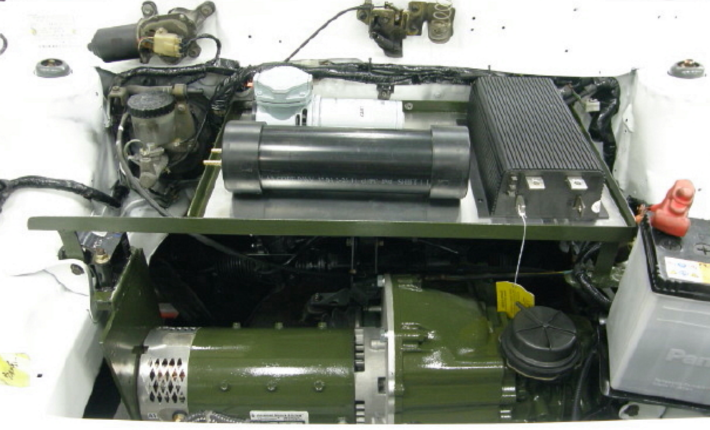

The compact drivetrain. Hyper 9 motor with a custom adapter and coupler attached to the reduction gearbox and attached to the subframe. Note that the original Figaro engine mounts are welded to the subframe, and the battery box can sit on top of this structure. No holes or welding to the car structure are allowed, hence the use of the original engine mounts, albeit with new, stiffer bushes. SEE PICTURE 3 BELOW

Here is the drive train bolted into the Figaro engine bay. It looks like it was always meant to be this way. SEE PICTURE 4 BELOW.

I’d decided that 4 battery modules, totalling 27kwh, would be the minimum acceptable to get a sensible range. At 30V each, four modules in series give 120V, which is perfect for the Hyper9 motor to run on. The next step is to design a battery box, which must be steel, basically blast and fireproof.

More CAD, first battery box mock-up. SEE PICTURE 5 BELOW.

Battery box v1. It’s a weird shape because the space left is weird!. Note pipe outlets to allow for battery cooling. SEE PICTURE 6 BELOW.

Here is v2 of the battery box in place with the modules inside. There is now a lot of stuff packed under the Figaro bonnet, but there is still a lot of equipment to fit in the car to make it work. SEE PICTURE 7 BELOW.

This was the easy part! I’m familiar with modifying cars and fabricating things but what came next was the biggest wiring job I had ever undertaken, especially when I have no electrical training or qualifications! I do have a friend who has done a conversion whom I could contact occasionally when I get stuck or confused. I’ve only included a few photos of the main parts.

Junction box. Includes the contactors which bring the high voltage circuits to life, mounted to the side of the battery box. Next to it is the main service disconnect, which can be used to disconnect the batteries when you’re working on things. The black thing is the blast vent, a requirement for when things go bad! SEE PICTURE 8 BELOW.

Bottom boot area behind the spare wheel. Includes the Main battery charger, which takes mains voltage from the charging socket mounted where the fuel filler used to be. DC – DC converter, uses 120V from the main battery pack to power the 12V circuits for lights etc. A tiny 12V battery. The high voltage cables are threaded through the vehicle using existing holes to the engine bay. SEE PICTURE 9 BELOW.

Passenger side of the engine bay. Note wiring threaded through the existing engine loom hole and high voltage heater wiring through ac pipe holes. The junction box is for the high-voltage heater. SEE PICTURE 10 BELOW.

The motor controller is buried in a dark corner of the battery box. The small wires are for controlling the motor, but are not connected at this stage. SEE PICTURE 11 BELOW.

EMUS BMS is now installed. This monitors and controls all 32 cells in battery modules. Monitors the battery modules during the charging process. SEE PICTURE 12 BELOW.

Battery box buttoned up. Note the Tesla electric brake servo at the top of the picture and the humidity monitor (white) at the bottom of the pic. It’s important that the battery and control systems are kept dry, and this allows me to keep an eye on them. Note that the washer fluid reservoir has been relocated to under the wing! SEE PICTURE 13 BELOW.

Interior shot including new gauges, motor controller, gear lever etc. SEE PICTURE 14 BELOW.

The only giveaway. SEE PICTURE 15 BELOW.

I haven’t included other bits and pieces such as the heater box, cooling system, Prius throttle pedal, Aliexpress gear lever, driveshafts, suspension changes etc, just to keep theings simple. I hope this gives everyone an idea of how involved the process is and why it costs so much. I’ve bought about £15k of components and have spent about 1000 hours on this car.

Outstanding stuff:

1. Had no room to fit an electric power steering pump so switched to a K10 Micra steering rack instead. The steering is fine now. A car as light as a Figaro shouldn’t need power steering and it would reduce range.

2. Air conditioning – a future project which I think can be done at a cost.

3. Second battery box in rear to increase range.

The car has an MOT and has been approved by DVLA as an electric vehicle and is now in daily use!

If anybody else is brave enough to want a Figgy converted, contact me at rhydavonpaul@outlook.com

BUILDER: JAMES BROWN

Builder: James Brown

Country: England

Website: https://www.fig-leaf.org

Date: March 2020 (Start)

Name: Fig Leaf

Range: 120 Miles (Target)

Charge Time: Pending

Battery Type: Lithium

Mission: The aim of Project Fig-Leaf is to convert our Figaro into an inspiring classic electric vehicle using components from the Nissan Leaf. By making this conversion straight forward and affordable, we want to encourage future conversions to update the Figaro for the 21st century.

Progress Updated – 28th September 2020

Member James Brown shares a video of the first Test Run, which includes the Speed Test, Torque Test, and reverse and regeneration braking test. The finished design is now undergoing testing with the new engine mounts and driveshafts. Next, he will be installing the drive system into the Figaro, and after some drive tests, the next step will be fabricating battery boxes and installing a charger.

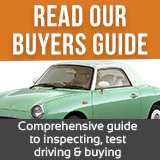

How the Fig Leaf will work

While all EVs vary significantly in design, there are some characteristics that they all have in common: They all use a method of storing energy (usually a high voltage battery). They all use motors to convert the battery’s stored energy into motion. They all need a controller (or inverter) to deliver the energy from the battery to the motor(s). Finally, they all need a way of recharging their battery.

In the case of Fig-Leaf, the battery will be stored in the boot. While this means you’ll need to find somewhere else to put your luggage, the weight distribution on the car will be a lot more balanced, meaning it should handle a lot better and brake more effectively.

You can see that the Leaf’s electric motor delivers energy to the front wheels in just the same way that the Figaro’s engine would. It’s actually much simpler as the electric motor uses far fewer moving parts and it is a lot more efficient, quieter, powerful and far more reliable. To give you an idea, the Leaf motor provides over 100bhp and over 200ft/lb of torque producing a top speed of around 82mph.

The motor gets its power from the inverter. This takes the direct current (DC) energy stored by the battery and converts it to an alternating current (AC) signal. The inverter also receives position information from the motor as it rotates so it can time this signal correctly, a bit like the valve timing on the Figaro’s petrol engine.

Unlike the Figaro’s engine, the Leaf motor delivers its maximum torque from a standstill. This means that whether you are pulling out from a junction or joining the main road, the Fig-Leaf will be able to accelerate when you really need it to. But the more power you demand and the faster you drive (cars create a lot of drag at higher speeds), the less efficient your car becomes and the quicker you will drain the battery.

When the car is fully charged, the aim will be for it to travel around 120 miles.

Just like filling up a petrol car, your battery will eventually need to be recharged. Like most EVs, the Fig-Leaf will have a built-in charger which will take power from an AC or DC source to charge the battery. Most modern EVs also use DC fast charging methods like CHAdeMO and CCS and this will be available for the Fig-Leaf at a later date.

Current Progress: After years of interest in electric vehicles and owning several Nissan Figaros (one that was destined for the scrap heap), the idea was born to create an electric Nissan Figaro using parts of a Nissan Leaf to make the Fig-Leaf as authentic as possible. Having researched many existing conversions, we visited Fully Charged Live in 2019 to ask the experts. Several companies who convert classic cars to electric confirmed that because of power losses from Figaro’s automatic gearbox, you would not be able to get very good range by simply swapping out the engine for a motor as has been tried in the past. So this got me thinking: What if you swapped the whole drive system? My online research led to Damien Maguire’s YouTube channels and as luck would have it, he was running an EV conversion course in October 2019 which I attended and learned the basics needed to start the conversion.

Meanwhile, the sad news came that our Figaro was beyond repair. This meant that we would need to source a replacement Figaro body to be able to build the car up from scratch. The next task was to find a donor Leaf. Thankfully we were able to source a 2013 Nissan Leaf from a scrape auction and so began the gruelling process of removing the components needed for the conversion. Once that was done, we set about reassembling and testing the electronic drive system outside of the vehicle. So far so good. Once testing is complete we will begin assembling the new drive system within the vehicle so we can make any final changes to the design. This is an ongoing project and currently, we are looking to source the right body shell (if you have one please get in touch). Once that is done we will be able to begin assembly.

Build Blog: James has recorded the build in a blog Read now

Picture Gallery (latest are posted at the bottom)

The Leaf. Buying a Leaf from a salvage auction like Copart can be a cost effective way to get the components you need. I picked this 2013 Leaf up from Chester for £2.5k

High Voltage Components. All of the HV components needed to convert your own vehicle to electric

Open Battery. Now the battery is removed, it’s time to start disassembly

High Voltage Components Removed. Now that the usable components have been removed it’s time to have the Leaf recycled.

Prius Battery. The battery I bought for testing was completely DoA and worse still, it had been built from scrap cells so there was no chance of recovering it.

Things have been a bit hectic with work but the project is starting to come on leaps and bounds now. I’m just looking for an engineering firm to measure and turn the Figaro spline pattern onto the leaf outer CV joints. Then I should be in a position to mount the motor into the test frame and get the wheels spinning. 1st June 2020

BUILDER: GARY KLYNE

Builder: Gary Klyne

Country: United States

Website: https://youtu.be/R2TKA-wze_c

Date: July 2019 (Start)

Range: Farthest to date – 89 miles, but haven’t done single-trip, full-to-empty test yet.

EV Motor: Netgain HyPer9 144 dual-shaft AC Electric Motor

Motor controller: Netgain X144 with chill plate

Transmission: Stock Figaro 3-speed automatic transaxle, typically left in 2nd gear

Throttle control: Used Prius hall effect pedal Maximum motor efficiency: 94.9% Maximum torque: 220 Nm Horsepower: more than stock Figaro 0-60: faster than stock Figaro

Battery: 6 used Tesla 5.3kW modules from a 2013 Model S with 30,000 miles on the odometer. Usable voltage range: 90 – 148 volts

Battery Management System (BMS): Orion 2 with Wi-Fi monitoring

On board charger: Elcon HK-J-H198-46 with J-1772 EVSE

Wall charger: JuiceBox Pro 40 Amp @ 220 volts with Wi-Fi monitoring

HV cables: 2/0 flexible welding cable wearing prisoner orange insulation jacket

DC converter: Meanwell HRP-600-12. 53 Amp/12 Volt output Pack

Cooling: Used Tesla 12V water pump with Nissan radiator fluid Module

BMS tap boards: Stealth EV Charge rate: 20 miles per hour @ 30 Amp Empty to Full charge: about 6 hours (includes balancing)

Extras: Upgraded rear coil over suspension for a Nissan Silvia handles the 350lbs of battery weight.

Initial problems: The biggest hurdle is designing and fabricating the bell housing plate and motor coupler for the torque converter connection.

Tip: get a good machine shop and be willing to pay extra for faster service. Motor controller and BMS configuration documentation is sparse and highly experimental. One wrong setting can severely affect performance. Loose connections and poor soldering can also wreak havoc.

Pros: Quicker off the line and faster response while in motion. Much quieter than a stock Figaro. No more stinky car exhaust or leaking fluids (unless you didn’t get a good seal on your cooling lines). Your spouse will get the exercise they need when you run out of charge and they get to push.

Cons: Range anxiety is a real challenge, especially in the beginning when you have nothing to compare expected results to. Wiring is complicated. One wrong connection and the car won’t move. There is no instruction manual for your exact build.

Watch Video

BUILDER: Speedwell (Osaka Electric Car)

Builder: Speedwell (Osaka Electric Car)

Country: Japan

Website: http://www.speed-well.jp/contents/gravure/no039/

Date: March 2011

Name: EV Figaro

Range: 50km to 100km

Charge Time: 8 Hours

Battery Type: 200 V Lithium

Description: The stylish Figaro was built by specialty company Speedwell. Make your dreams and hopes come true with in-house technology. At Speedwell, we will pursue the values of Figaro, and we will provide stylishly tailored Figaro to all of Japan. Beautiful electric car high-quality genuine leather seat that creates a high-quality space. Product specification (planned) enjoy riding and watching. We are committed to the wiring colour around the motor, the arrangement of control amplifiers and batteries, and pursued a primitive EV conversion that is beautiful and full of charm. No compromises are allowed in the interior, and the seat and lining will be redesigned with the finest leather. In addition, colour order is possible, and finish is given with favourite interior colour.

Note: No pricing was issued at the time of publication and we are not aware if any cars being sold

Picture Gallery

The promotional image of the EV Convert

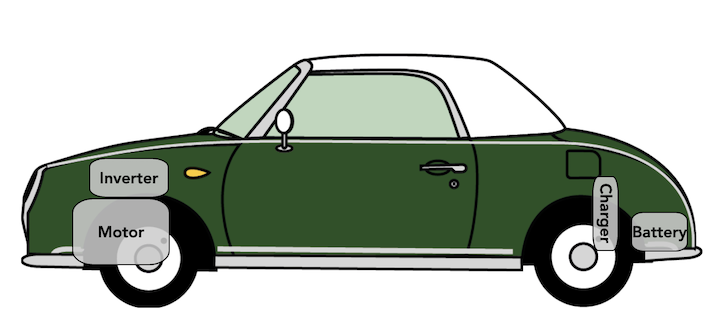

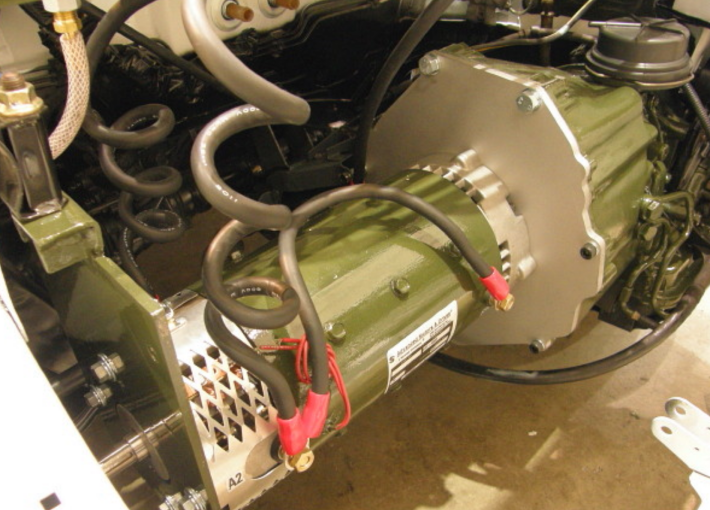

Working out how to connect the motor to the existing gearbox

The motor is ready for installing

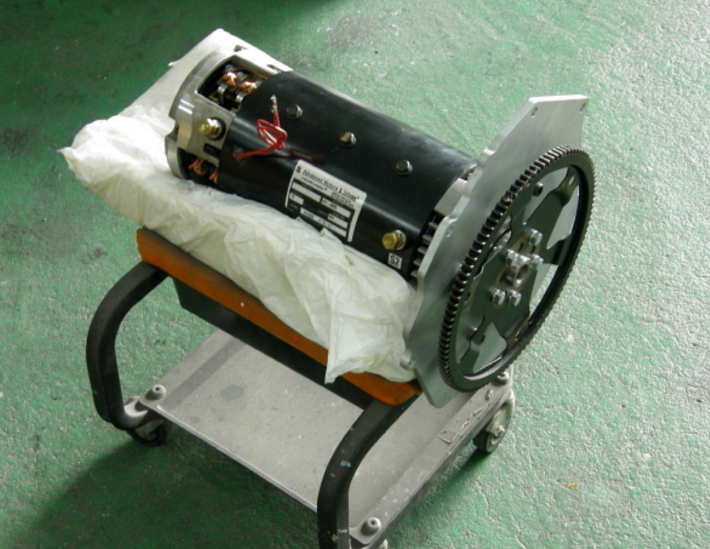

Connected to the gearbox

Installed into the engine bay

Additional equipment required was secured to a platform above the motor

Wiring completed

The motor is secured with additional supporting frames

Neat installation with room for some additional luggage!

The car was exhibited at the Electric Vehicle Industry Exhibition, Tokyo Big Sight, on October 27-29, 2011. Joined the Osaka Prefecture University EV Consortium from March 2011 to establish a low-carbon society at Speedwell. The EV Figaro was designed and developed in an effort to find a way to survive in the next generation in considering of the future of automobiles. Under the slogan of value rather than cost, a new wave of electric cars in Osaka called “OSAKA EV Nouvelle Vague” has started now.